Our national experience has developed methods which produce the best stucco structure most economically. Our recommendations include a sound substrate, metal reinforcement where necessary, the correct preparation of masonry surfaces, the proper materials for the base coat, and the California Stucco finish coat for a strong and durable finish. All these have a direct bearing on a satisfactory stucco job.

- When scratch and brown coats are applied, two coats of approximately 3/8” each or a combined minimum thickness of 3/4” are required prior to finish coat.

- It has become an accepted practice to double back with the brown coat as soon as the scratch coat is sufficiently rigid to accept the second coat. The two coats can be put into place in a single day.

- Moisten base coat for a minimum of two consecutive days.

- Allow two weeks for base coat to cure prior to applying finish coat.

- When applying finish coat lay out to permit the completion of the entire wall surface or elevation in one operation. If this is impractical, the finish coat shall be carried to some natural breaking point, such as doors, windows, belt courses, inside and outside corners.

- On retaining walls, install conventional California Stucco, do not install Texture-Flex, Rollflex or Elastocote.

- When using Texture-Flex, Rollflex or Elastocote do not use galvanized accessories, use vinyl or zinc.

- Do not apply waterproofing to cement stucco. Doing so may cause rusting and damage the stucco.

- Do not apply finish coats in direct sun light and complete each elevation in the same day.

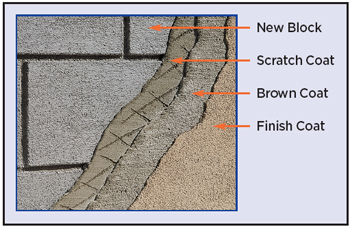

New Block/Brick

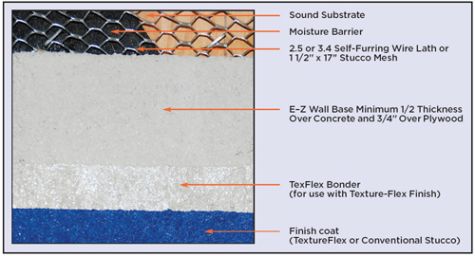

Install Portland scratch and brown coats or E-Z Wall Base Coats to a minimum of 3/8″ then California Stucco finish coat as in the case of frame construction. Masonry surfaces not sufficiently rough enough to provide a good mechanical key (i.e. monolithic concrete) and where metal lath is not required, a dash coat should be applied providing the surface is free from oil and other elements that would inhibit an adequate bond. California Stucco finish can then be applied. Exterior acrylic bonding agents may be used in the preparation of the masonry substrate but only under direct supervision of a journeyman plasterer.

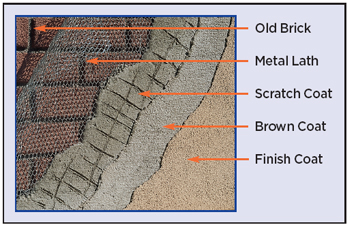

Install metal reinforcing using self-furring galvanized mesh, nailing into horizontal joints. Apply Portland scratch and brown coats, or E-Z Wall and California Stucco finish coat as in the case of frame construction. In the case of painted masonry where powerwash or sandblasting does not reveal a good mechanical key, this procedure is required. Exterior acrylic bonding agents may be used in the preparation of the masonry substrate, but only under direct supervision of a journeyman plasterer.